About us

Established in 1997, Hong Deh specializes in metal processing technology and precision parts manufacturing. We are a reliable partner with the belief of "humble service, dedication to high-quality craftsmanship, and the pursuit of sustainable development."

Application Fields

With advanced composite processing equipment, we can manufacture complex components for various industries, including optical communication, pneumatic parts, medical devices, automotive components, electronic structural parts, and automation equipment

Professional Techniques

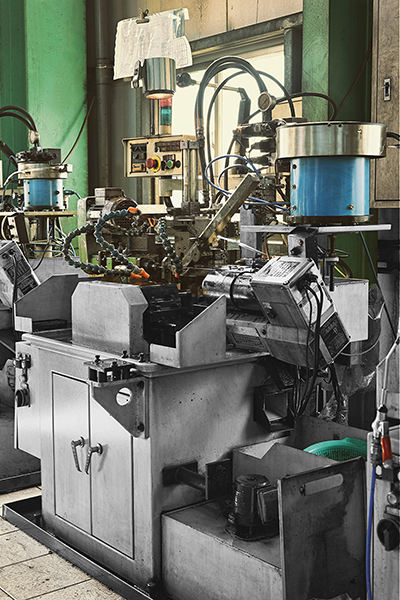

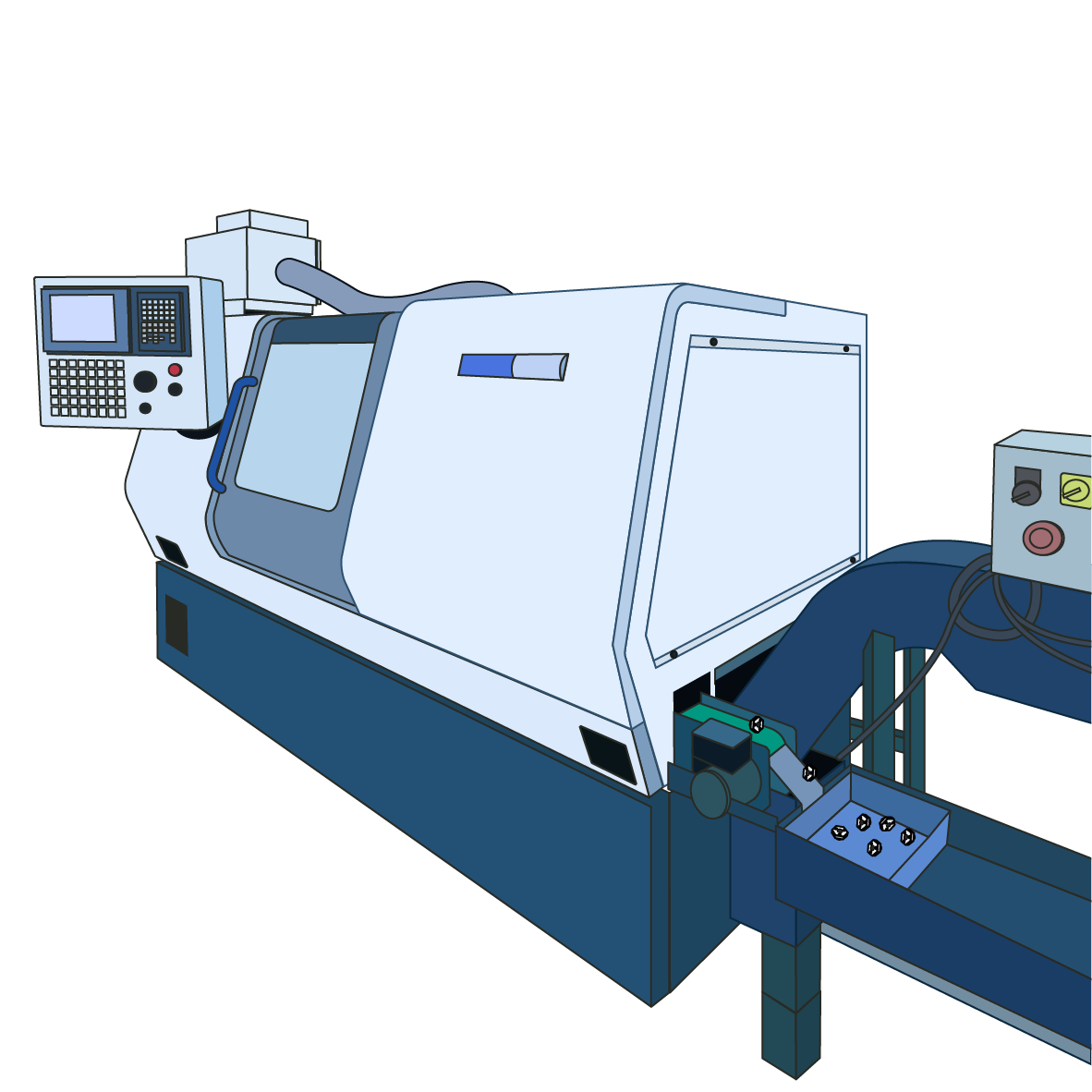

Equipped with efficient CNC machining equipment to satisfy the different needs of various industries. Facilities: Japanese-imported dual-axis dual-turret turning and milling composite machines, back-spindle turning and milling machines, and both sliding and fixed-head lathes.

- Machining Range: φ 0.5mm~ φ 65mm

- Precision: 0.01mm

- Total Machines: 70 units

Specialized machines handle processes such as drilling, tapping, and grooving. These machines enable high-volume production and cost reduction. We currently operate 35 specialized machines.

We offer various surface treatment services to enhance product performance and durability, including: Electroplating Anodizing Heat Treatment Sandblasting Grinding

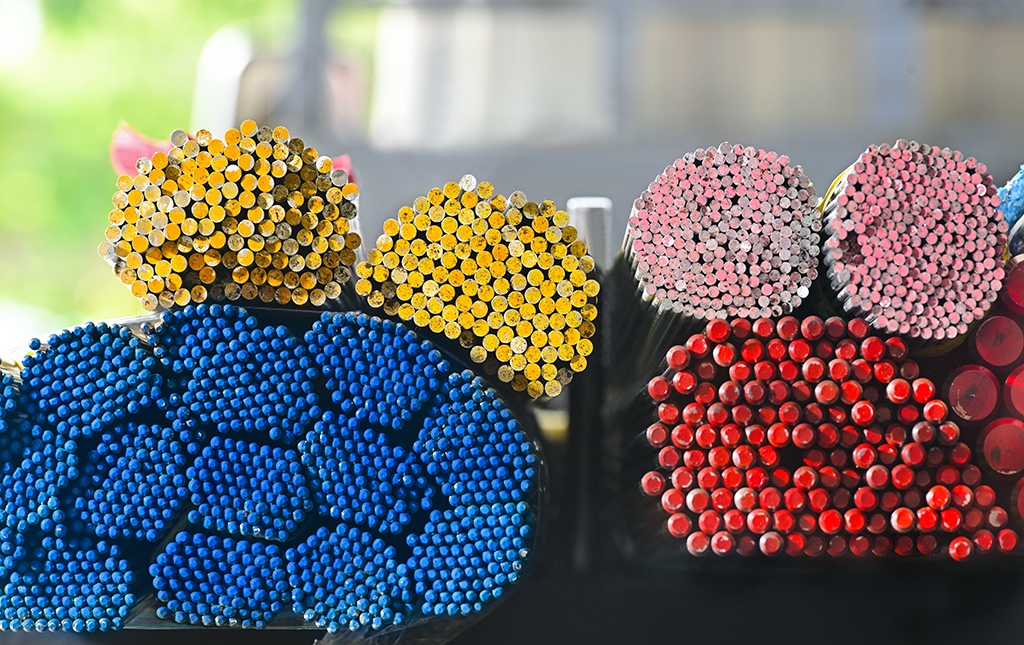

We process a variety of materials, including:

- Brass: C36000, C3601, C3604, C6801, Lead-free brass

- Stainless Steel: SUS303, SUS304, SUS316, SUS416, SUS420, SUS430, SUS440C, SUS630

- Aluminum: AL2011, AL2024, AL5052, AL6061, AL6063, AL7075

- Free-Cutting Steel: 12L14, 1215, 1144

- Carbon Steel: 1015, 1018, 1020, 1045

- Alloy Steel: SCM415, SCM420, SCM435, SCM440, SUJ2, AISI8620

Flow Chart

Video Area

Would like to know more about our service? Please visit our youtube videos.

.jpg)